How to make a sandwich tube with your own hands?

Brick chimneys are gradually being replaced by new onesconstructions. When they are manufactured, new building materials are used. Such chimneys are called a sandwich-pipe. They have a lot of advantages. However, the high cost does not allow everyone to purchase the presented construction.

With a great desire to collect a sandwich-pipe with your own hands will not be a big deal. Detailed instructions will help the home master to perform all the actions correctly. In this case, he can not only collect the pipe, but also mount it independently on the roof.

general characteristics

The design, like a sandwich tube, appeared on themarket of building materials relatively recently. Production technologies are constantly being improved. There are new types of materials that allow you to mount any system, to give it the necessary qualities.

Mounting the sandwich-pipe yourself will save money from the family budget. The production of such chimneys is not very complicated. The presented constructions can be made of materials that are presented in construction shops.

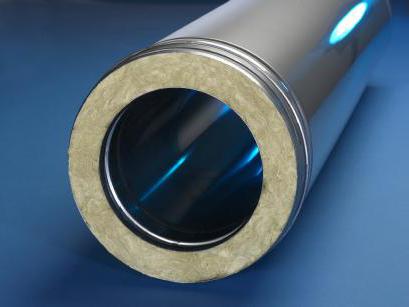

A sandwich tube is a construction ofmetal and insulation. As the latter, incombustible materials are used, for example, basalt wool. Also in the structure there are two pipes of different diameters. In the cavity formed between them, a heater is installed. It is thanks to the simplicity of such a pipe that you can assemble it yourself.

Benefits

Making a sandwich pipe do it yourself is justified for many reasons. The presented design has a lot of advantages. The first thing to note is the versatility of the sandwich pipe. It is compatible with chimneys from virtually any material.

This is a compact and lightweight product. It is easy to mount by yourself. And the work will be done literally in one day. It looks aesthetically pleasing, able to complement the general appearance of the roof from different materials.

One of the main advantages presentedchimney is incombustible. Basalt wool, which is used as a heater, does not burn or smolder at high temperatures. She just turns to stone.

Rafter system does not prevent installationsandwich pipe. On the walls of the chimney soot will not settle, condensation will appear. Therefore, the system does not need to be cleaned often. The materials from which the pipe is made are not exposed to corrosive media, chemicals, or temperature drops.

disadvantages

A list of sandwich tube flaws is enoughmodest. The designs presented in sale cost rather expensive. This disadvantage does not matter for those owners who want to make a similar chimney with their own hands.

It should also be noted that the sandwich constructionnot used for over 15 years. This is also a doubtful flaw. The market of building materials is constantly being improved. If in the manufacture of the pipe to use new, high-quality materials, they can last longer.

According to professional builders, the presented systems have many advantages that overshadow the disadvantages. It is for this reason that many owners create sandwich pipe do it yourself. For bath wooden construction presented option is considered the best. For other types of materials it is also suitable.

Preparation

Mounting the sandwich-pipe yourself performed by a certain technology. It includes several stages. First you need to make a drawing. To do this, carry out appropriate measurements, think through the necessary details.

After creating a plan, you can purchaserequired amount of materials. You should also prepare all the necessary tools to work. Next is the assembly of the structure and its installation on the roof.

For the manufacture of such a system will requirepurchase a sheet for the inside of a stainless steel pipe, heat insulation and an external sheet for the pipe, which can be galvanized steel, brass or copper. The selection of materials should be given special attention. On this will depend on the functionality and durability of the chimney.

Choice of materials

Studying the question, how to make a sandwich pipe with your own hands, you must responsibly choosematerials. The inner pipe section should be made of stainless steel sheet. This material changes its size during heating and is not deformed. Galvanized steel is best used only for the outer part of the pipe. Brass or copper may also be suitable for this.

Insulation between two metal partschimney can be made of mineral wool. This basalt fiber, which has a minimum thermal conductivity. Its thickness can range from 25 to 60 mm. This material is environmentally safe, does not ignite. This is a great option to create a chimney.

Also as a heater can be appliedexpanded clay or polyurethane. It is impossible to use flammable materials for fasteners, insulation and other elements of the system. A typical factory boiler can heat the system up to 120ºС. But here a homemade stove for a bath, for example, produces temperatures up to 800ºС in the chimney. Therefore, the materials must be chosen very carefully.

Making calculations

Installation of chimney sandwich pipes do it yourself should start with the calculations. In accordance with the plan of the house you can find the distance of the chimney to the surface of the roof. However, it is important to correctly calculate the parameters of the site, which will rise above the roof surface.

If the roof has a flat surface orthe minimum slope, the chimney should rise above it to a height of 50 cm. If the slopes are covered with flammable material, this figure increases by 2 times. The pipe must be in this case at least 1 m.

If the chimney is located at a distance of 3 m or more from the ridge of the roof, you need to correctly determine the line of its installation. It runs at an angle of 10º from the center of the roof.

You should also pay attention to the cross section of the pipe. For a 3.5 kW boiler, a chimney with a section of 14x14 cm is suitable. If this figure reaches 5 kW, dimensions should be 14x20 cm. If the boiler has a rated power up to 7 kW, a section of 14x27 cm should be made.

Pipe assembly

Make a sandwich pipe for the chimney with your own hands simple enough. Having prepared all the necessary elements, having carried out the calculations, you can proceed to work. First, you need to remove the film from all materials. If a factory-made boiler is installed, ordinary glass wool can be used. But for homemade stoves it is extremely important to use basalt fiber. After unpacking it is left for 5 minutes. This will allow the fibers to be cracked.

Steel pipe (often solid) requiredwrap a layer of insulation. The outer part of the chimney can be assembled from several fragments. Galvanized steel is collected using small screws. To mount with their help you will need both fragments and the surface of the sheet.

In some cases, steel sheets are joined whenwelding aid. It is important to ensure high tightness of the system In this case, it will be effective and safe. In the place where the pipe will pass through the roof, it is necessary to equip a special box. It is filled with expanded clay or other non-combustible material.

Chimney connection

Know how make a sandwich pipe with your own hands, not enough. It is important to correctly install the presented structure on the roof. This will require the purchase of special adapters. A pipe with a smaller diameter is inserted into the expansion of the previous section of the chimney. This method of connection avoids soot inside the system.

If the chimney passes through the wall, you needdisassemble the site for this process. This site will need to be strengthened. Next is going to the outer bracket. Special structural elements are attached to it, which will allow to easily move the tee in the process of fastening the chimney.

The wall through which the installation will be performed,can be covered with a 10 mm thick sheet of plywood. An asbestos sheet is installed along its perimeter. On this layer you will also need to mount a plate made of galvanized steel. All layers strengthen the screws in the place where the pipe will pass. Bracket should be painted. Next, the pipe is threaded into the prepared hole.

Rooftop installation

Can display sandwich pipe for chimney do it yourself through the roof. Inside, a galvanized sheet should be attached to the hole created. It is fixed only after the pipe is placed on the roof. If necessary, it can be brought under the edge of the roofing material.

If the pipe is high (more than 1 m), you needconsider a system of spacers. Otherwise, such a system would be unreliable. Crimp clamps are also used. This will avoid the inclination of the pipe from the wind. When installing the struts should take into account the wind rose in the area.

If the roof is made of bitumen or roofing material, the material is additionally protected from fire. To do this, install over the coating deflector. It has in its design a grid damper.

Pipe joints should not go through the ceiling or roofing material. This is the most fire hazardous places of the chimney. The owner of the house should be able to control the joints.

Mounting

Sandwich pipe do it yourself need to fix properly. All knees, tees and joints must be tightened with hose clamps. It is especially important to consider the height of the chimney. Such structures must be properly fixed, strengthened.

At the joints of the sandwich pipes, the clamps are tightened. If there are tees or adapters, you will need to use two mounting elements.

Support can be created from the corners of 50, 30 mm. It is also important to apply heat-resistant sealant. This substance prevents air from entering the pipe. If you do not ensure the tightness of the system, the thrust in it will be insufficient. Carbon monoxide can get into the room.

Final stage

Sandwich pipe do it yourself must be properly mounted. It should be noted that the distance of the entire chimney should be a total of 5-6 m. The distance is measured from the tip to the grate. Sealant will need to handle all the joints. Also, the space between the two pipes on top of the need to handle the presented means. The circle with insulation should not remain open.

Pipes are treated both indoors andoutside. You should also seal the joints on the outside of the chimney. Moreover, after starting the system, all connections should be carefully checked. In the presence of leaks, the joints are once again treated with a sealant that can withstand temperatures up to 1000 ºС.

Having learned how to assemble sandwich pipe do it yourself you can create a chimney yourself inaccording to building codes. At the same time, it will be possible to save money from the family budget, to mount a solid, durable system that will not need to be restored for many more years.