Classification of premises for the risk of electric shock (PUE and GOST)

Where work is related to electricity, alwaysthere is a possibility of electric shock to a person. The influence of unfavorable conditions of the external environment is further aggravated by the fact that the human body is capable of exerting little resistance. And if the room has high humidity, then the probability of electric shock increases, as the sweat of a person very well conducts it. There is a classification of premises for the risk of electric shock. GOST provides for three classes.

Classification of premises without increased danger

In such rooms, the normal temperature andhumidity, no dust, the floors are made of materials that do not conduct current (usually wooden), there are no grounded objects or their number is minimized. These rooms allow the use of an electrified tool with a voltage of 220 volts. Classification of premises for the risk of electric shock includes:

- rooms for the work of administrative and managerial personnel;

- centers of computer facilities;

- auxiliary, instrumental and dispatching rooms.

Classification of premises with increased danger

Such premises are characterized by:

- relatively high humidity of air, exceeding 75%;

- temperature with a constant or periodic mark on the thermometer of 35 degrees;

- conductive dust, which covers the wires and internal surfaces of electrical equipment;

- floors, conductive current. They are made of materials such as metal, brick, reinforced concrete, and can be just earthen.

The room belongs to the category of increasedIf there is at least one of these characteristics. Classification of premises for the risk of electric shock of this class applies to the production premises of enterprises associated with vehicles, maintenance and repair areas, thermal and welding departments.

Classification of premises of special danger

They differ:

- excessive humidity of air, which reaches 100%, which causes condensation in the room;

- the presence in the room of chemical aerosols, conductive current, as well as vapors, liquids and gases, which gradually destroy the insulation and conductive parts of electrical equipment.

Particularly dangerous is the room affectedmold, as it, along with chemical gases, can also destroy the insulating layer. It is inadmissible that moisture penetrates the building from the outside. Constant rainfall will make it particularly wet, and, therefore, extremely dangerous. Especially dangerous is considered and such a room, which is characterized by two or more conditions at the same time. This classification of premises for the risk of electric shock refers to:

- Storage facilities in which combustible-lubricating materials and dangerous goods are stored;

- battery and paint shops;

- washing and steaming chambers.

On the territory with the placement of outdoorElectrical installations are classified by the classification of premises for the risk of electric shock. PUE (Rules for the installation of electrical installations) contain the basic requirements that electrical installations must meet. The territory can be fenced or not. It is necessary that the electrical equipment has reinforced insulation.

In cases of electric shock to an objectIt is necessary to exert an influence on the flame (with ignition) by any fire-extinguishing agents. This is ordinary water. But there are drawbacks here. Since water has an increased electrical conductivity, it should not be used in case of ignition of electrical installations with high voltage. In the case of extinguishing oil products, the situation is complicated by the fact that they continue to burn on its surface. In these cases, chemical foam and powder formulations are used.

In order to prevent electroporation, it is always always possible to reduce the risk to a minimum, namely:

- Apply protective fences around electrical hazardous areas. Such protection will help to avoid close contact with objects under voltage and as a result, to protect against electric shock.

- The use of interlocking will help avoid an accident if current access is restricted due to malfunctioning equipment.

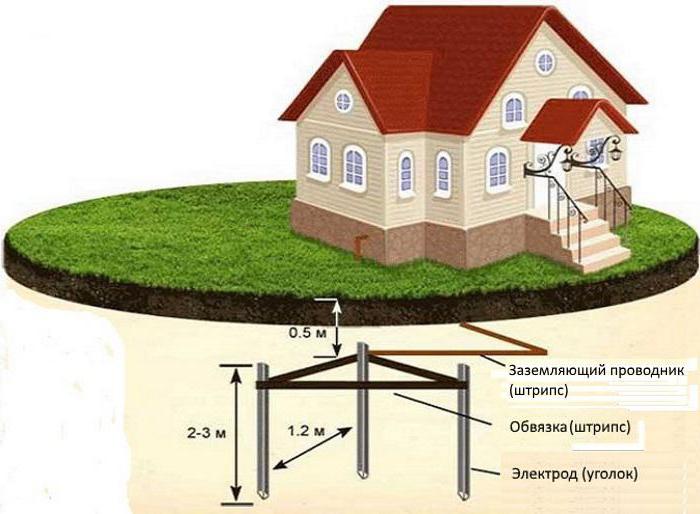

- To avoid accidents, use theportable earthing switches, especially if the work is carried out in open areas where there is direct contact with the ground. The earthing switch will send electricity, in the event of an overvoltage situation, to the ground.

- Observe technical safety measures using protective insulation (rubber mats, etc.).

In the normative documents, a special groupwork performed under adverse conditions. For example, in boilers, apparatus, vessels made of metal, where the possibility of moving the operator and his exit from the enclosed space is limited. In this regard, there is a classification of premises for the risk of electric shock. Therefore, the requirements for safety conditions are higher than in rooms with special hazards.